Ceramic Products - an Overview

Ceramics is a collective term for a large number of products that vary widely in composition as well as in their artistic and industrial applications. The definitions of certain ceramic products have also changed in the course of time, so that it is rather difficult for a non-specialist to find his way through the jungle of many terms, technical descriptions, historical developments and artistic fields of application.

I have therefore decided to make a brief excursion into the terminology before the actual aim of this chapter, namely the description of ceramic products in kerosene/paraffin lamps.

"Ceramics" is the name given to all products obtained by firing inorganic, clay-containing minerals and earths at high temperatures. Depending on their chemical composition and on their firing temperature, the produced ceramic products differ in their appearance, in their properties and accordingly also in their possible applications.

I am not an expert on ceramics. My interest in it is primarily aroused by the many lamps in my collection that are either entirely or partially made of a ceramic material. With my wife Maria Antonietta also came a love of porcelain, which prompted me even more to learn more about these products and how they are made. I have pored over many reference books, consulted Wikipedia in German and English, and gathered together here what might be of interest to the collector of kerosene/paraffin lamps. I am not concerned with all ceramic products with their very ramified technical uses, but only with the types that were used to produce artistically valuable objects of daily use (which also include the kerosene/paraffin lamps).

In this context, a distinction is made in Germany between two main groups:

a) Ceramic earthenware (terracotta, majolica, faience, non-vitreous stoneware)

b) Ceramic sintered ware (stoneware, soft porcelain, hard porcelain)

Note: The distinction introduced in Germany between "Steingut" (= non-sintered earthenware) and "Steinzeug" (= fully sintered ceramics) does not exist to this extent in the UK. For both Steingut and Steinzeug, only the term “stoneware” exists. I have therefore translated Steingut as non-vitreous stoneware and Steinzeug as stoneware.

Earthenware

Earthenware is the term used to describe those ceramic products that are fired at relatively low temperatures and thus either do not sinter their components at all or only partially. This makes them porous and permeable to water, but completely impermeable to light. Sintering is compression of the individual mineral components initiated at high temperatures, which fills all pores as sintering progresses. The extent of sintering depends not only on temperature, but also on the type of minerals used and their quantitative distribution among each other. Earthenware includes majolica and faience, terracotta and non-vitreous stoneware.

Historically, majolica was the name given to those ceramic wares that were first brought to Italy by Arab traders from the island of Mallorca (hence the name; Majolica is the old Italian name for Mallorca). In Italy, especially in the 15th and 16th centuries, ceramic producers made high-quality, finely painted majolica, which were in great demand. Majolica is fired at approx. 950-1040°C and has a white to light red-brown, porous body. After an initial firing at low temperature, the majolica vessel is coated with an opaque white tin glaze. On the dried but not yet fired glaze, the desired motif can be painted in colour, whereby the colours are very well absorbed by the still very porous glaze layer. Only then is the final firing carried out, whereby the glaze and the colours it contains melt into a shiny layer with bright colours. It is only with this glaze layer that a majolica vessel becomes impermeable to water.

Faience is in itself identical to majolica, as the techniques of production, glazing and painting are very similar. The name derives from the Italian city of Faenza, the second famous center of majolica production after Urbino. In France, the term faïence has become established, as the coveted products were probably first sourced from Faenza in Italy.

In the late 19th and early 20th centuries, these two terms were applied to different types of glazed earthenware, which also used coloured glazes. There are very many kerosene/paraffin lamps with colour-glazed and colour-painted vases that are consistently referred to as majolica, regardless of their glaze type and colour design. According to my personal observation, ceramic vessels that have a completely smooth, non-relief surface are now predominantly called "faience" (especially in France), whereas ceramics that have a relief-worked surface tend to be dubbed "majolica" (predominantly in German-speaking countries; in France they are called "barbotine").

Terracotta is actually unglazed earthenware, usually fired at low temperatures of 900-1000°C, with a reddish colour due to the iron oxides present in the clay. The commercially available unglazed plant pots in a predominantly red colour are the best example of terracotta vessels. The name means "cooked earth" in Italian. Terracotta vessels are permeable to water.

Non-vitreous stoneware (Steingut in German) is a ceramic product invented in the 18th century, which is fired at much higher temperatures (up to 1250°C) than majolica and terracotta to a white to light reddish-brown body, but is still porous due to the fact that it is not completely sintered and thus belongs to earthenware. Jasperware of Wedgwood is a non-vitreous stoneware from Great Britain that was in great demand worldwide. In the middle of the 18th century, the Englishman Josiah Wedgwood succeeded, after much experimentation, in inventing a hard ceramic that is somewhere between earthenware and stoneware and which, unglazed and coloured with a few pastel colours, achieved world fame. The Japanese Satsuma vases are also made of non-vitreous stoneware. To make this type of ceramics waterproof, lead-based glazes are often used, which are melted at around 1000°C.

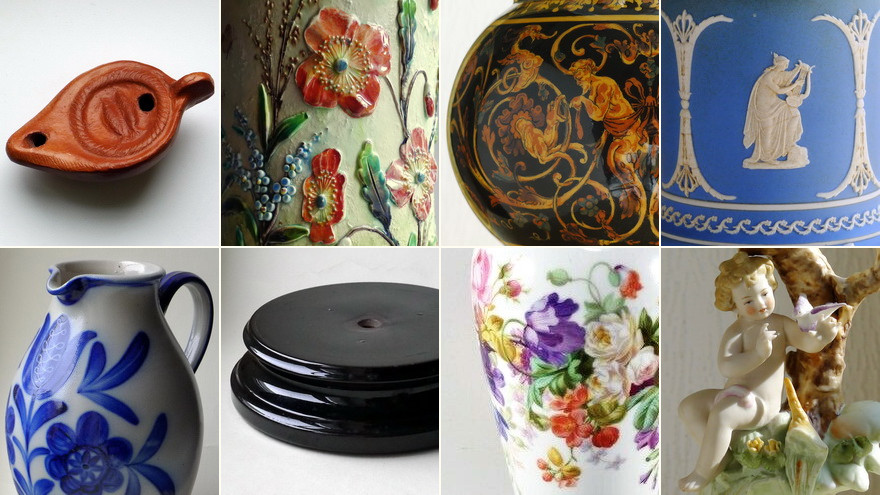

Some examples of ceramic products made from earthenware (top row) and from sintered ceramics (bottom row)

Top row, from left: Oil lamp in terracotta

Lamp vase in relief majolica (L.097)

Lamp vase in smooth faience by Gien (L.335)

Lamp body in jasperware by Wedgwood (L.332)

Bottom row, from left: German salt-glazed stoneware jug

British lamp base in black glazed stoneware

Lamp vase in glazed porcelain (L.020)

Figural candlestick in bisque porcelain by Porzellanfabrik Kalk (L.330)

Sintered Ceramics

Sintered ceramics are those ceramic products whose components sinter completely during the firing process at high temperatures, thus producing a non-porous, waterproof body. Sintered products include stoneware and porcelain.

Stoneware consists of a completely waterproof, but unlike porcelain, not translucent, mostly light-coloured body, as it is fired at temperatures of 1200-1300°C, which causes its basic materials to sinter completely. Unglazed stoneware can be ground, cut and polished like stone. A well-known early example of this is Böttger stoneware (precursor of hard porcelain). Salt-glazed stoneware from Westerwald, Germany, in the form of jugs, bowls and pots with sparse painting in dark blue on a light grey-bluish background used to be very common in Germany. Most of the round ceramic bases of British kerosene/paraffin lamps are made of high-quality stoneware, densified by higher firing temperatures and glazed glossy black.

Porcelain is the best-known representative of sintered ceramics. For a long time, it had to be imported at great expense from China and Japan, as its composition and production were not known in Europe. The extraordinary properties of porcelain (its hardness, high thermal and mechanical resistance, translucency, insensitivity to many chemicals, impermeability to water) have made it a much sought-after art object and collector's item in Europe.

The name of porcelain derives from the Italian porcellana, the name for a species of snail whose highly polished, yellowish-white shell bore quite a resemblance to Chinese porcelain, the first specimens of which probably reached Italy with Marco Polo when he returned to his homeland after his long stay in the Far East.

Porcelain consists mainly of kaolin, quartz sand and feldspar. It was this composition containing kaolin that enabled Johann Friedrich Böttger to fire the first European hard porcelain in 1708. A very important feature of porcelain is its translucency with thin shards. This property comes about because feldspar melts at high firing temperatures but cannot form crystals again when it cools. The proportion of feldspar in the porcelain therefore remains a glass-like solidified melt, which is what makes the porcelain translucent. Its translucency distinguishes porcelain from all other ceramic products.

Hard porcelain has a higher kaolin content and is fired at very high temperatures up to 1480°C. A well-known example of hard porcelain is, for example, Imari porcelain (= Arita porcelain) from Japan. Most porcelains made in Europe are also hard porcelains.

Soft porcelain has a lower kaolin content and is fired at a slightly lower temperature (up to 1350°C) than hard porcelain. The earlier Chinese porcelains are made of soft porcelain.

Bone porcelain is a British invention in which bone ash (calcium phosphate) is added to the porcelain mass. This composition gives the porcelain wares a particularly high impact strength and also higher translucency. Bone porcelain ("bone china" in English; "china" is the early English term for porcelain ware from China and is still used today as a synonym for porcelain) belongs to the group of soft porcelains.

Biscuit porcelain is an unglazed, white porcelain that was used to make busts and statues because of its visual similarity to white Carrara marble. Biscuit porcelain also belongs to the soft porcelains.

Frit porcelain (also called pseudo-porcelain) is the result of European efforts to produce real porcelain when it was not yet known that kaolin was an essential part of it. Frit porcelain is therefore not porcelain but an earthenware, as it does not contain kaolin and its components do not undergo sintering during firing.

Porcelain production involves several steps and different firings. The watery slurry of the finely ground raw materials (English term: "slip") is poured into prepared moulds made of plaster. The porous plaster walls of the mould absorb the water from the porcelain slurry so that a somewhat dehydrated and thus somewhat solidified porcelain layer is formed on the contact surfaces. The excess slurry is poured out of the mould again and the resulting porcelain vessel is air-dried until it is "leather-hard".

This is followed by a first firing at a relatively low temperature (approx. 900-1000°C). During this firing, the porcelain mass loses the remaining water, shrinks by 10-15% and solidifies. Since sintering has not yet taken place, the body produced is quite porous and can absorb a liquid glaze very well. After the glaze has been coated, the actual final firing takes place at the high temperatures mentioned above, during which the sintering of the components, the vitreous melting of the feldspar and the melting and bonding of the glaze with the porcelain surface take place.

| IMPORTANT on my own account: I cannot distinguish the different ceramics from each other because their relevant distinguishing features such as colour and water absorption of the shards are hidden under glaze and therefore not testable for me. The only remaining test is light transmission, which can always be done. With this, one can always distinguish porcelain from the other ceramics that are not translucent. Therefore, I have taken the liberty of referring to all ceramic products that are not translucent simply as "ceramic", regardless of whether they are earthenware, majolica or stoneware. I have thus divided all ceramic products relevant to lamp collectors into two groups that are very clearly distinguishable even by laymen: A. "Porcelain" for all translucent products B. "Ceramic" for all other products that are not translucent. The ceramic experts may forgive me! |

Light test to distinguish between porcelain and other ceramics

(upper row: normal photograph; lower row: illuminated from inside).

From left: Vase made of relatively thin porcelain, completely translucent (L.274)

Porcelain font with relatively thick wall, translucent except for the thick parts (L.205)

Porcelain lamp of thick, textured porcelain, nevertheless translucent (L.085)

Ceramic vase, completely opaque even with very strong light source (L.105)

The Painting of Porcelain and Other Ceramic Objects

The coloured design of porcelain can be done both before the glaze is applied with "underglaze colours" and on the applied but not yet fired glaze with "inglaze colours". These colours must be very temperature-resistant in order to survive the high temperatures of the final firing undamaged. On-glaze decorations, on the other hand, are applied after the final firing and fired at lower temperatures (in muffle kilns), during which they melt and combine with the glaze. Since high temperature resistant colours are not necessary here, one has many more colours and shades available. Golden decorations and decorative lines can only be applied as an overglaze colour. Since they probably do not bond properly with the glaze, these decorations are not completely abrasion resistant.

The paints used for painting porcelain and other, high-quality ceramic vessels are enamel paints, which consist of finely powdered glass, appropriately temperature-resistant metal oxides for colouring, suitable organic binders and water and are worked up to a thin liquid mixture (see also the subchapter Emaille, Cloisonné, Champlevé).

Of course, porcelain objects that have been painted very finely and in great detail by hand are very valuable and had correspondingly high prices. However, as a result of the onset of industrialisation and the rationalisation that accompanied it, ways were found to print decorations and pictures on porcelain and other ceramic vessels instead of painting them by hand. The transfer printing process was invented in Great Britain as early as the mid-18th century. In this technique, motifs to be printed are engraved on copper plates, which are then covered with printing ink. After cleaning the surface of the plate, the printing ink remains only in the engraved (= lowered) lines. This image is then printed on a suitable paper. This process is similar to the traditional copper engravings for books. Now the printed paper is fixed with the image side down on the ceramic vessel and fired. During this firing, the paper burns away and the printing inks from the paper are melted on the ceramic surface. This process, of course, only allows printing in one colour. Each additional colour requires the procedure to be repeated. Most plates and other utilitarian tableware with monochrome printed landscape motifs in the 18th and 19th centuries were created using this technique. Because of the mass production of the utilitarian ware, transfer printing was more commonly applied to earthenware. Porcelain wares for wealthy buyers were still painted by hand at that time.

In the first decades of the 20th century, hand painting and transfer printing were combined by transfer printing the outlines of the decorations and pictures in dark colours (usually black) and colouring the areas between these outlines by hand. Goods coloured in this way were nevertheless marketed as "hand-painted", although there is no question of proper painting here; an outlined area was merely filled with a colour. Therefore, these objects should rather be called "hand-coloured".

With the development and perfection of machine printing techniques at the end of the 19th and beginning of the 20th century (e.g. rotogravure, 4-colour offset printing, silk-screen printing, etc.), it has since been possible to apply complicated, multi-coloured decorations and images to ceramic objects by now printing these multi-coloured motifs on transparent plastic films, fixing these films to the surfaces of the ceramic products and firing the prepared pieces. It goes without saying that the colours applied are not simple printing inks (as in newspaper and letterpress printing, for example), but are made of temperature- and light-resistant inorganic pigments. Most utility porcelain of the 20th century is decorated in this way.

The distinction between completely hand-painted, completely printed or partially printed and then hand-coloured objects can easily be made even by a layman with a high magnifying glass and some experience. Hand-painted objects can always be recognised by their individual brush strokes and clear outlines with sharp edges. Printed outlines can be recognised by the fact that the lines are not completely drawn but partially interrupted. Smoothly drawn black lines without slightly frayed edges cannot be achieved with any machine printing technique. In the next photo I have shown all three techniques.

Examples of hand-painted, hand-coloured and printed motifs on porcelain (some greatly enlarged)

Top row, from left: Hand-painted flower on a porcelain vase (L.020)

Hand-painted chinoiserie scene on a Moderator lamp (L.329)

Hand-painted flower on the same lamp (note the black outlines, which are also hand-painted)

Hand-painted porcelain by Rosenthal with black printed outlines and hand-coloured areas.

Bottom row, from left: Hand-coloured tea service from England with black printed outlines and rather imprecise hand-colouring

Printed tea service from the Art Deco period (probably silkscreen)

Printed tea service from the 1960's (probably lithography)

Printed porcelain mug from more recent times (probably gravure)

The coloured design of the other ceramic products (majolica, faience, earthenware, etc.) is in principle done exactly as described above for porcelain. Presumably, the historically correct inglaze painting on majolica and faience (see above) was considerably expanded at the beginning of the 20th century with coloured glazes and overglaze painting, in order to make unhindered use of the large colour palette available for this purpose.

An interesting method of painting pottery is slip painting, in which a watery, relatively viscous clay slurry (= slip) coloured with the desired colour is applied with brushes or other means to the leather-hard dried but not yet fired pottery vessel and then fired. The colours applied in this way stand slightly raised on the background, as their clay content burns with them and remains on the surface. The French term for slip is "barbotine". Ceramics painted with slip are also simply called barbotine in France. However, this term is often used incorrectly for ceramic vessels that were cast in high relief from the outset in appropriately prepared moulds. Their pronounced relief does not come from a layer of slip applied later. Engobe is a very thin, coloured or uncoloured clay slurry that can be used to completely cover or partially paint leather-hard dried ceramics like a glaze. Engobe painting does not result in higher colour surfaces.

Use of Porcelain and Ceramics in Kerosene/Paraffin Lamps

Ceramic products were very often used as vases, pillars or even whole lamp bodies without a separate font in kerosene/paraffin lamps. The most commonly used ceramic products were probably majolica (or what was very casually called majolica around 1900) and porcelain. High-quality lamps with finely hand-painted porcelain vases or with porcelain sculptures were of course reserved for financially strong customers.

Lamps with vases made of hand-painted earthenware were probably very common in Germany and Austria. These products were called majolica, even though their colour design deviated from the historically handed down painting technique. An attractive variant are the pieces cast with a beautiful relief pattern, which were then painted with different colours. This resulted in very embossed surfaces painted in contrasting colours, which is the charm of these lamps. These embossed decorations were appropriately incorporated in the casting moulds. Flowers, plants, but also stylised art nouveau decorations were very popular. These ceramic parts, called majolica, were used with preference for table lamps (mainly with Vesta shades) and hanging lamps. Unfortunately, the vast majority of these lamps are not marked with signatures or marks, so that the identification of the manufacturing company is virtually impossible.

Other lamps, on the other hand, were painted with slip colours that gave a slight relief without the need for relief patterns on the moulds. Many French lamps (barbotine) and also lamps from Austria were coloured in this way. These lamps also do not bear any marks.

French ceramic manufacturers Longwy, Gien and Vieillard became world-famous for their decorative objects such as vases, plates, jardinieres, etc. painted with intensive, pastose enamel paints. Of course, they also made lamp vases for both Moderator and kerosene/paraffin lamps. The Gien manufactory also succeeded in reviving Italian Renaissance motifs in a range of ceramics that has become famous.

Ceramic vases with openwork walls are particularly elaborate decorations. The Hungarian manufactories Zsolnay and Ignác Fischer excelled with this technique. Their high-quality lamps were intended especially for export to Great Britain, but also for wealthy, discerning customers in Austria and Germany. Today they are relatively rare and correspondingly expensive.

In Great Britain, too, lamp parts for kerosene/paraffin lamps were produced by well-known ceramic producers. The most famous were Wedgwood (with the famous "Jasperware") and Royal Doulton. However, they did not make their ceramic parts into lamps independently, but produced the desired goods on behalf of the lamp manufacturers. The ceramic vases by Taylor, Tunnicliffe & Co. have become famous for their deliberately jagged and roughened surface. Lamps with the ceramic parts of these three producers are rare and expensive, as they are coveted collectors' items for British collectors.

The only German ceramics manufacturer I know of who also made vases for kerosene/paraffin lamps is Franz Anton Mehlem in Bonn (L.221). I do not own any lamps from other German ceramic manufacturers.

The Japanese Satsuma vases, often converted into kerosene/paraffin lamps in France, are discussed in the sub-chapter Ceramics from Japan and China.

Examples of colourful and sculptural design in ceramic lamps

Top row, from left: Pastose enamel painting on cobalt blue ground (L.149)

Delft-style painting, Fourmaintroux Frères, France (L.305)

Relief enamel painting, Longwy, France (L.145)

Fine painting on roughened surface, Taylor, Tunnicliffe & Co., Great Britain (L.271)

Bottom row, from left: Openwork and painted ceramic vase, Ignác Fischer, Budapest (L.163)

Majolica vase with heavily reliefed surface (L.026)

Jasperware lamp by Wedgwood (L.332)

Sculptural lamp with boys and flowers (L.082)

Porcelain, historically considered the noblest ceramic product, was as well used for various types of kerosene/paraffin lamps, just like earthenware, majolica and stoneware. Here, too, one finds all kinds of designs from simple, thin-walled, smooth porcelain to highly structured porcelain worked in relief or even shaped into sculptures. The focus, however, is now more on artistically high-quality painting. Since many famous porcelain manufactories participated in the production of lamp parts, these pieces almost always bear the corresponding porcelain marks.

Of the German porcelain manufactories, Meissen in particular has been committed to the production of porcelain lamps. There are lamps from this world-famous company with different designs, but almost always with the famous "onion pattern". The Meissen lamps always achieve high prices, which are probably also due to the high prestige of this company, which is recognised worldwide. There are finely painted lamp vases from the Berlin manufactory KPM, which were used by Wild & Wessel in their lamps. The Thuringian manufactories Sitzendorf and Schierholz produced mainly porcelain lamps with putti and applied plant ornamentation, which were in demand in Great Britain. Carl Thieme from the Dresden area produced very different porcelain lamps, all with fine painting, mainly for export to the USA. Thuringian manufactories in Rudolstadt and Volkstedt specialised in producing fine porcelain in the Italian Capodimonte style. Whether my lamp L.065 (see photo) also comes from one of these manufactories is not clear, as for once it has no porcelain mark.

In France, there were two porcelain manufactories that made beautiful porcelain bodies for the Moderator oil lamps. The manufactory Valentin St. Gaudens in the south of France (not to be confused with the so-called "Valentin lamps") had created its own style with finely painted floral arrangements in cobalt blue coloured and gold decorated frames. Bayeux in Normandy specialised in imitating Chinese scenes in the Canton style. Many Moderator lamps with the porcelain vases from these manufactories were later converted into kerosene/paraffin lamps. Similar Chinese scenes are also known from the Parisian porcelain manufacturer Samson.

Many French porcelain lamps produced by different, small manufactories in and around Paris have remained completely nameless. The porcelain of these manufactories is simply called "Parisian porcelain"; company names, porcelain marks, etc. are completely missing. These include not only the so-called Valentin lamps (see chapter French Lamps in the collection section), but also porcelain vases, some of which are very finely painted.

Great Britain is a country where stoneware enjoyed as high a reputation as porcelain. Therefore, there is a large number of very beautiful British lamps that were made of ceramics (probably mainly stoneware). They are beautifully painted and sophisticatedly designed. In addition, there were also porcelain manufacturers that produced excellent porcelain lamps. Here, the company of Moore Brothers must be mentioned first and foremost. This company created its own remarkable style of fully sculptured putti and plants that perfectly reflected the taste of the time. There are many lamps of varying sizes by Moore Bros. that always command high prices. Other very renowned manufacturers such as Royal Worcester or Spode Copeland are also known to produce excellent kerosene/paraffin lamps, all of which are of the highest quality. However, their prices are also correspondingly high.

Of the other porcelain manufacturers known to me, Royal Dux Bohemia (now in the Czech Republic) is worthy of mention; they are known to have produced fully figural porcelain groups for lamps. Imari vases from Japan were often used in kerosene/paraffin lamps in France (see subchapter Ceramics from Japan and China).

Examples of colourful and sculptural design in porcelain lamps

Top row, from left: Fine floral painting by KPM, Berlin (L.166)

Fine flower painting by Valentin St. Gaudens, France (L.234)

Chinese style painting by Bayeux, France (L.106)

Reliefed porcelain imitating Chinese celadon, France (L.270)

Bottom row, from left: Porcelain vase with strongly structured surface, Parisian porcelain (L.085)

Sculptural relief in Capodimonte style, probably from Thuringia (L.065)

Nursery lamp with fully sculptured flowers, Great Britain (L.215)

Sculptural lamp with putti and flowers, Moore Bros., Great Britain (L.252)